Update: Mudita Pure Development Status

The majority of Mudita's operations are now being done remotely, this is a brief update the status of our development. The only team physically present in the office is the engineering team, as their work relies on access to specialized equipment and various devices.

This has been limited however to an absolute minimum, and precautionary measures have been introduced, such as masks, gloves and the maximum number of people allowed to be in the office building at the same time.

T4 prototypes

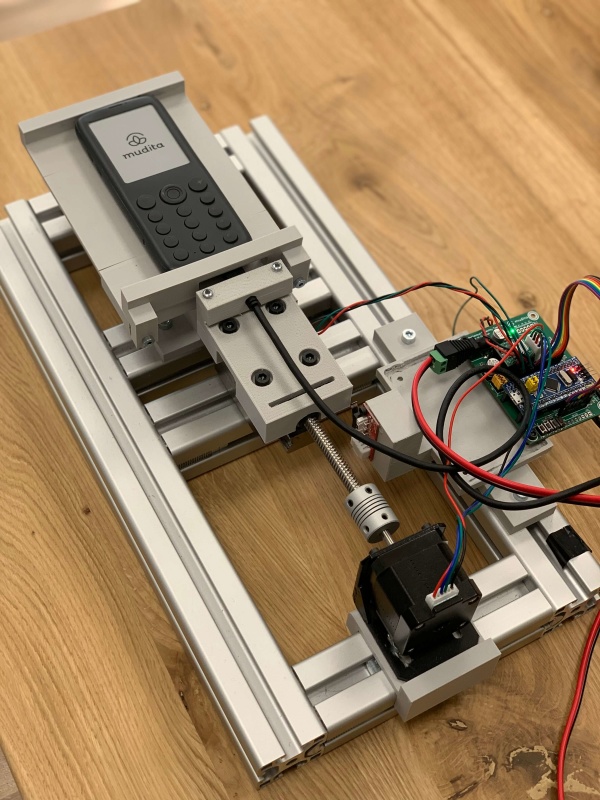

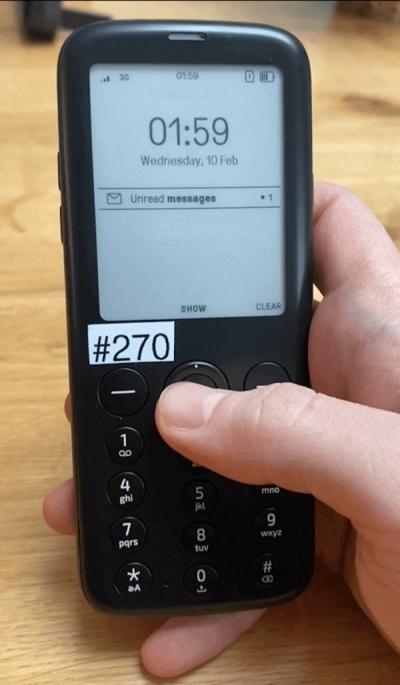

In the previous update, we showed you the production process of the T4 PCBs. We’ve finished the assembly of 11 prototypes, which are now being tested. In April, we’re going to finish introducing corrections to the PCB and will be ready to construct the final one, T5, which will be used in Mudita Pure. At the beginning of May, we’re planning to produce the first tranche of 100 final PCB.

We’re using the already built prototypes to run the radio tests and confirm the SAR value of Mudita Pure. One of them is already in the Verkotan laboratory (a FINAS and ILAC accredited testing laboratory) in Finland, which is widely considered as one of the best laboratories in the world for these kinds of tests.

Pure’s SAR is being measured in the EU units (amount of radiation per 10g tissue). At this moment, we are testing two configurations: one in which the source is at a 0 mm distance from the body (our priority test), and a second one, in which the distance is set at 5 mm. The latter configuration (5 mm) remains the one used by the majority of other phone producers and shall be used by us for comparison purposes.

These analyses will allow us to further optimize the parameters, before the final testing and certification that will be performed in May. We will keep you informed about the results

Mudita Pure prototype tests in Verkotan lab, 16 April 2020

Mudita Pure prototype tests in Verkotan lab, 16 April 2020

Trial assembly

Together with our partners from the factory that will be manufacturing Mudita Pure, we’ve been testing the assembly process that you could read about in the previous update. We have confirmed its reliability while adding some finishing touches and corrections. This is great news for our partners developing the molding forms, as they have now the final confirmation that they can proceed with the production.

This is great news for our partners developing the Mudita Pure molding forms, as they have now the final confirmation that they can proceed with the production.

Molding forms

Our partners are already building the molding forms - at this moment, we’re in the process of milling them in steel blocks. Some of them have already passed the trials and are now being optimized for mass production. In June we’re planning to have the first complete casing sets.

One of the most challenging parts of the casing is the lid - it’s quite a big element, while at the same time very thin. We’ve decided to make a test molding form and check whether the assumed thickness of 0.8 mm would work. The tests showed that it’s in fact too thin: the color wasn’t distributed evenly and the casing was too limp. We’ve decided that we should aim at 1mm instead to achieve the right feel. This molding form test will also allow us to achieve the desired color in the injection process and perform graining - giving the molding form, and thus the casing element, a final desired structure. We’ve been planning to do both of these in mid-April - unfortunately, due to the ongoing global lockdowns, we’ll need to wait a couple of weeks until the situation gets stabilized. At the moment we’re not experiencing any meaningful delays in Mudita Pure development due to the COVID-19 pandemic. Our partners and factories continue to operate while introducing all the necessary precautions. We are doing our best to work according to our schedule, but can't foresee the impact of possible further restrictions - we sincerely hope the situation will come back to normal as soon as possible.

If you have any questions, feel free to comment below and join the conversation on our forum. If you’re interested in sharing your experiences with us or writing a guest post for us, send us an email via hello@mudita.com!

Please feel free to get in touch via social media (send us some photos or videos too), you can find us on Facebook, Twitter and Instagram, let’s connect! To learn more about Mudita, take a look at our website and our other posts. If you enjoyed reading this article, please share and recommend it! We need to go online to find people who’d like to spend more time offline.

Related stories

Mudita's MWC 2024 Recap: Innovations, Insights, and Inspirations

Mudita's debut at MWC 2024 marked a significant milestone, allowing us to showcase our unique philosophy of mindful tech in a sea of digital innovation.

The Mudita Gambit: Chess Takes Center Stage

We chatted with leading Polish chess players during the Warsaw Chess Festival. Dive behind the scenes of the chess world.

Mudita Pure Production Update - February

With a lot of activities moving forward in the Mudita Pure production process, we’re here with another update.

If you'd like to receive the best stories from our blog, keep up to date with our progress and get notified about our product releases and special discounts.